Electric cars: platforms at the heart of the transition

To support their ambitions in terms of electric vehicles, manufacturers are using dedicated platforms. MEB, E-GMP, CMF-EV…: as many acronyms as different technologies for the latest electric cars.

Car manufacturers do not hesitate to invest billions in their electrification strategy, with platforms for electric cars at the center of their plans.

A platform is the basic structure of a car, including at least its chassis. The choice of one platform or another when designing a new model can determine many elements, such as the engines that can be adapted to it and the on-board technologies.

The advantages of a platform dedicated to electricity

When a manufacturer wishes to develop an electric car, several options are available to it. It can adapt one of its platforms for thermal cars to electric by using (or not) the bodywork of an existing vehicle, or start from a blank sheet and develop a dedicated platform. When a model offers the choice of a thermal or electric engine, like the Peugeot 208/e-208 , Renault Twingo and other Kia Niro/e-Niro , it is therefore a platform for a thermal vehicle adapted to the ‘electric.

However, certain platforms were originally designed to accommodate thermal or electric engines, like the MLA (Modular Longitudinal Architecture) used by Land Rover.

However, there are many advantages to starting from a clean sheet, as Tesla demonstrates, and to developing a platform dedicated to electricity. In fact, the constraints of a thermal platform and those of another electric platform are different.

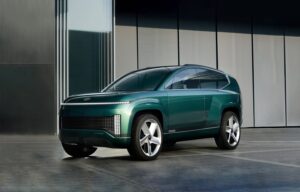

A dedicated architecture makes it possible to free ourselves from certain barriers and to better meet the requirements of an electric car, by reducing mass and consumption, for example. The main automobile groups have developed one or more platforms dedicated to electric vehicles, such as the MEB (Modularer Elektrobaukasten) and the J1 at Volkswagen Group, the CMF -EV (Common Module Family Electric Vehicles) for the Renault-Nissan-Mitsubishi alliance. , or the E-GMP (Electric Global Modular Platform) for Hyundai Motor Group (HMG).

Certainly more expensive to develop, dedicated platforms can still lead to savings for manufacturers thanks to lower production costs, provided they are produced in large enough series.

They have many other advantages. Space management, in particular, makes it possible to obtain better habitability for a given size. The new Renault Mégane E-Tech Electric , for example, has interior space comparable to that of a thermal Mégane in a more compact size of 16 cm. Conversely , certain models on platforms designed for thermal vehicles do not display the same optimization of space, even more so when they share their bodywork with cars with combustion engines. The long hood of the BMW i4thus shelters a large unexploited space, for example. If the electric sedan had been designed from scratch, it would likely have accommodated a shorter hood and, possibly, storage space (frunk). This is also the case for the i3 on a dedicated platform.

Likewise, most electric cars on a dedicated platform do not need a central tunnel or have a very low one, allowing the central rear passenger to travel more comfortably.

Despite these many qualities, mixed platforms are not expected to disappear anytime soon. The Hyundai group (HMG) plans to continue using them alongside dedicated platforms, certainly for cost reasons.

What is a modular platform?

The main platforms developed by manufacturers are called modular. This type of architecture, already widespread for thermal platforms, aims to limit the number of platforms used by a manufacturer by pooling them. This allows economies of scale, simplification of production and a faster development process for a unique model.

These platforms are therefore designed to allow different wheelbases and track widths. For example, Hyundai’s E-GMP platform covers segments C, D and E, i.e. vehicles from around 4.30 m to almost 5 m.

Two vehicles on the same modular platform can therefore be very different, unlike older platforms which did not provide such flexibility. The different elements, such as the running gear, can therefore differ between two cars designed on the same platform, and their road behavior will in fact be unique to each.

Unlike the majority of thermal cars with propulsion, electric propulsions have their motor positioned at the rear, directly on the axle (and not at the front, therefore). This architecture is not particularly more complex than traction.

As a result, some manufacturers opt for propulsion on models where one would not necessarily expect it, such as the Honda e or the two-wheel drive models on the MEB (Volkswagen Group) and E-GMP (HMG) platform. This provides more dynamic and sometimes amusing behavior. However, you should not be afraid of trickery behavior on these cars. Modern propulsion systems are not particularly popular outside of sports cars, where this is a desire of the manufacturers. The ESP of an electric Renault Twingo E-Tech, for example, will never let it go sideways.

However, not all manufacturers want a return to propulsion. At the Renault Nissan Mitsubishi alliance, for example, the CMF-EV platform and the future CMF-BEV have a traction architecture. The engineers explained to us that the choice of traction made it possible to bring together all the mechanics at the front of the vehicle, and thus avoid having to transport electricity and water (for cooling) to the rear of the car. This would have increased production costs and vehicle mass.

Likewise, electric makes it possible to offer four-wheel drive without a drive shaft, by simply integrating an electric motor on each of the axles. Under normal conditions, the car is driven by a single axle in order to limit consumption. However, with the added mass, four-wheel drive configurations can increase consumption and therefore decrease range. Thus, the Nissan Ariya SUV in the 87 kWh version announces up to 500 km of range in traction, compared to 460 km in the four-wheel drive e-4ORCE version. Before opting for a two-engine model, it is therefore better to ensure that you actually need the additional performance and off-road capabilities.

Post Comment

You must be logged in to post a comment.